Strip-LOK™ Joiner

Product Summary

A strip tear on a coil processing line doesn’t just cost the company time and money. It’s a major headache for the production crew whose job it is to repair the damage.

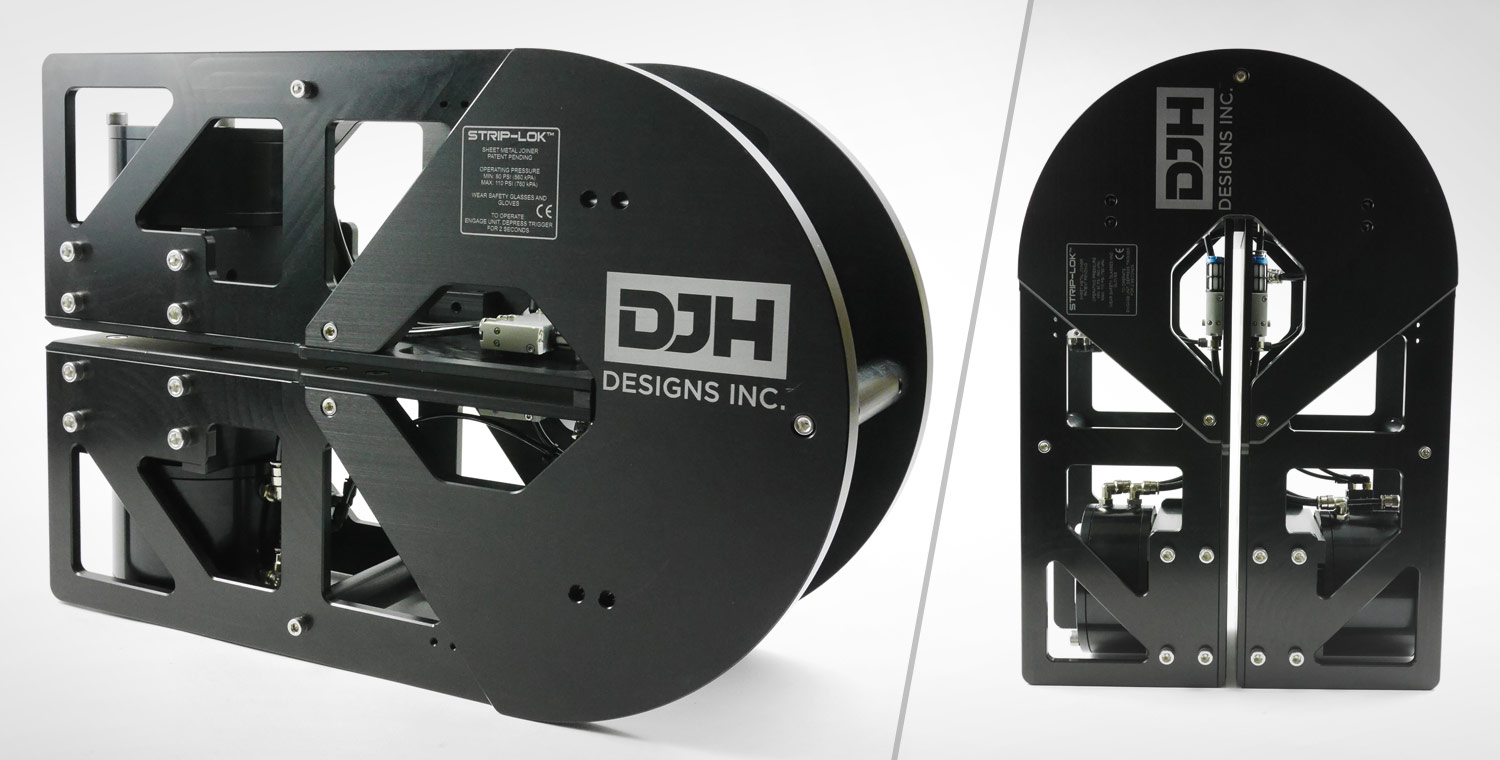

The Strip-LOK™ Sheet Metal Joiner is a portable strip-joining machine driven by compressed air. Unlike traditional coil steel joiners the main use for Strip-LOK™ joiners is repairing strip tear off situations on modern steel strip processing lines such as continuous galvanizing and paint coil coating lines. Two models are available to suit most production facilities. Designed for use with aluminum or steel substrates, this is the best advance in economical efficient and effective strip joining equipment in decades. Already used by most steel manufactures worldwide, the Strip-LOK™ Sheet Metal Joiner is highly appreciated and valued.

Repeatable, strong connections can be achieved with a total sheet thickness up to 1.8mm.

Operation is very clean and quiet as the Strip-LOK™ Joiner does not require any consumables other than the two pieces of strip to be joined and no blank is produced.

Principal of Operation

The joint is achieved by mechanically punching a square hole through the sheets to be joined and folding the flared strip back onto itself. Apart from requiring an external compressed air source the STRIP-LOK™ Joiner is fully self contained. The STRIP-LOK™ Joiner is activated as soon as the trigger is pressed and an automatic cycle of punching and flattening the two layers of metal strip will then commence. The joining cycle will immediately stop as soon as the trigger is released.

Joint Strength

The strength of each join depends upon the gauge and properties of the metal being connected. As a general rule, 20 punches on each side of .4mm soft iron sheets provide a tensile force of approximately 25kN (5620 lbf).

Long-Reach Heavy Gauge STRIP-LOK™ Joiner

Designed for wide strip, the LRHG Model has a reach of 300mm from the strip edge. It is not necessary to have individual joins across the entire width of the strip. Considerable stability is created in a joint of two overlapping sheets via a reasonable overlap region in the order of 700mm or more. This unit can be used to join strip widths up to 1500mm.

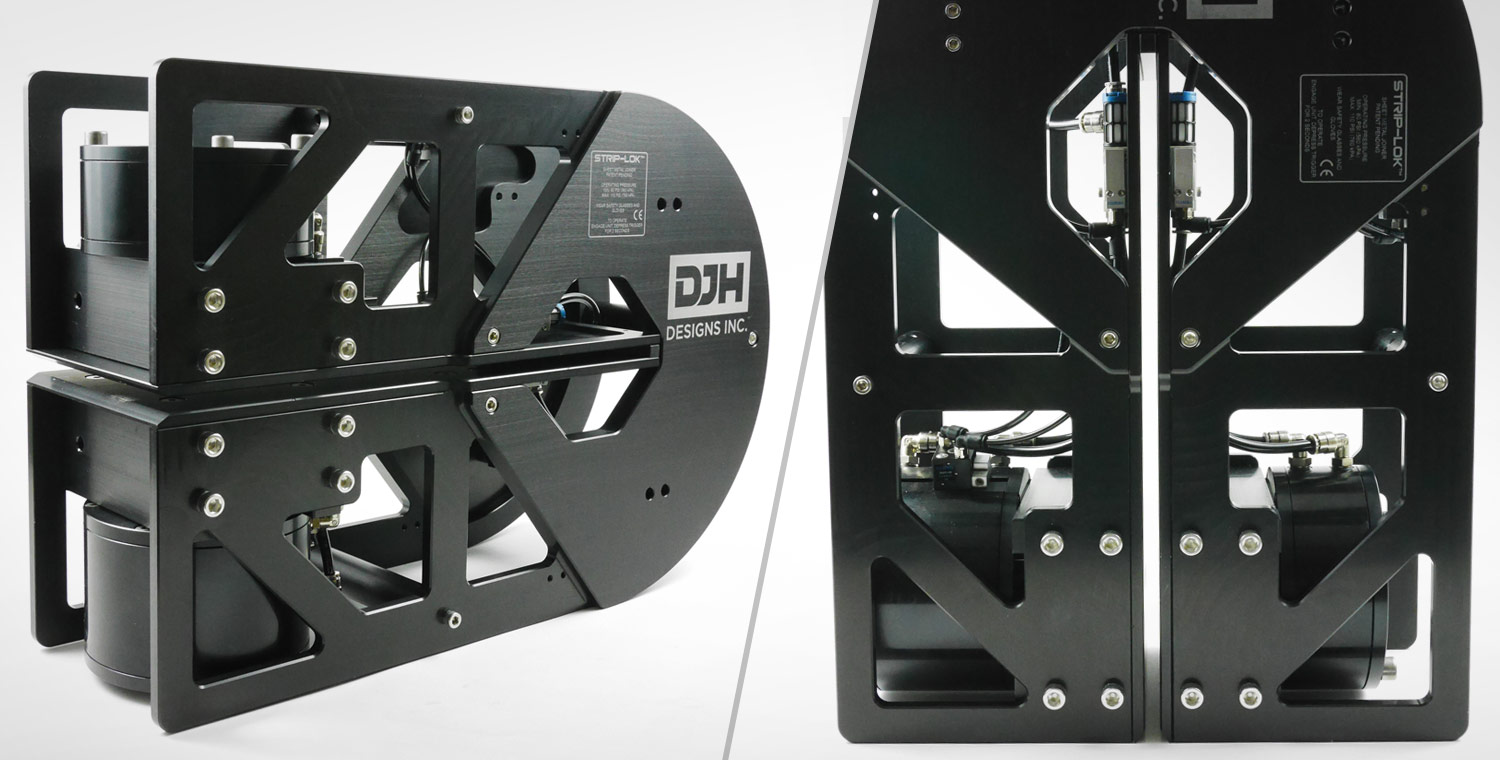

Long-Reach Heavy Gauge Low Pressure STRIP-LOK™ Joiner (LP)

The LP designation signifies that this model is designed for use in plants where achieving higher line air pressure is a problem. The LP model offers the same performance as the standard unit. However, only requires 450 kPa of air pressure to achieve the same capacity for joining the thicker/harder materials for which the standard unit would require up to 760 kPa to achieve.

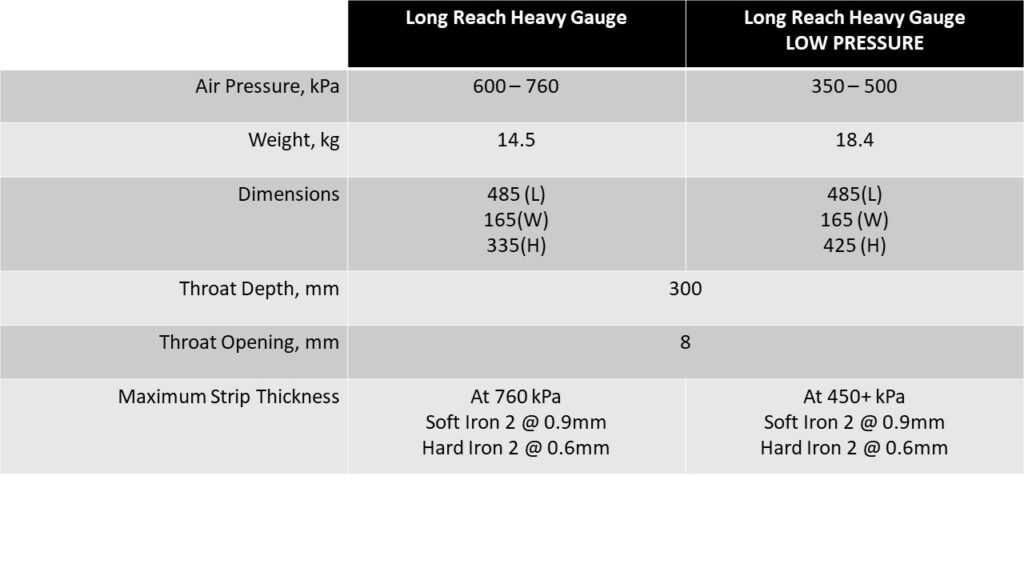

Strip Thickness, Capabilities & Specifications

Air Supply

Air supply pressure should be between 600kPa and 760kPa (85 – 110 PSI) for the standard unit, and between 350 and 500 (50-60psi) for the LP models, filtered, dry and lubricated. A minimum supply pressure of 700kPa (100 PSI) for the standard model, 380 kPa (55psi) for the LP Model is recommended to obtain the capacities as listed below.

Metal Limits

As the supply air pressure increases, so does the capacity of the STRIP-LOK™ Joiner to join thicker sheets. As a general rule the following specifications apply for the two models: