Weld Inspection System

Product Summary

KEY FEATURES

DJH OVERVIEW

DJH Designs’ cut and etch measurement system highlights

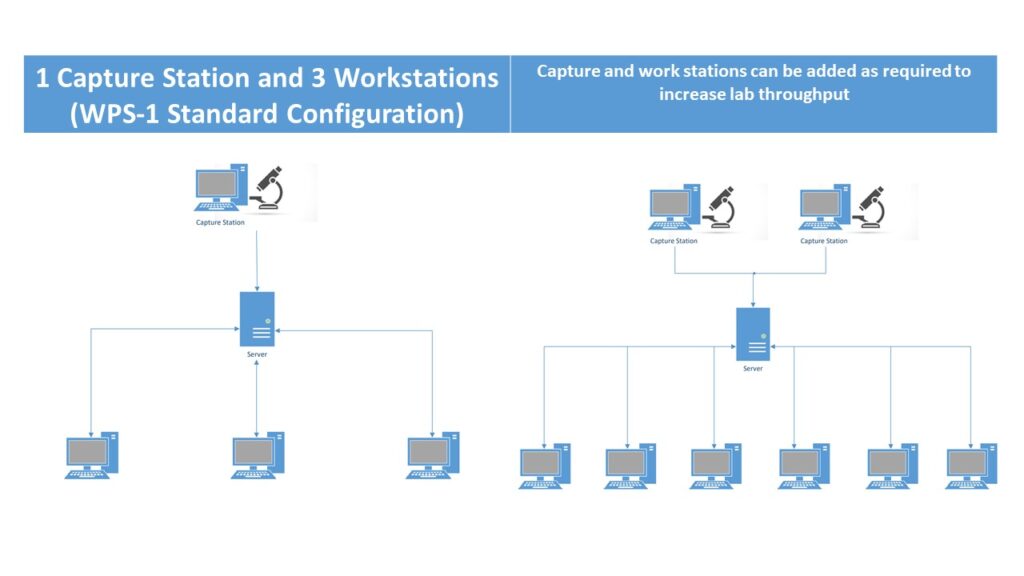

Our unique modular system approach gives clients the greatest flexibility possible in designing a system to meet their throughput demands. With our modular approach, there is no need to buy costly microscope hardware for each measurement station. One capture station is only required to capture and supply images for up to 4 workstations. The Capture Station can also be used as a workstation once all the image records have been created and captured. Need to increase throughput? Add another capture station, then add the required number of workstations to your system. Multiple capture stations, and workstations can be added to the system to meet the productivity capabilities of the lab.

The SQL system database has independent calibration control for each capture station in the system. Each saved image record contains within the record its own unique calibration profile so regardless of it being opened on a different workstation the image can be accurately measured or remeasured on any workstation.

Microscope types can even be mixed matched, for example if there are very large weld segments that need to be analyzed you can have one microscope on the system for your typical weld types, and a second one with a much larger field of view dedicated to analysis of large weld segments that you would not normally be able to measure on the other microscope. Any of the welds from the differing systems can be measured by any work station without any special considerations or modifications.

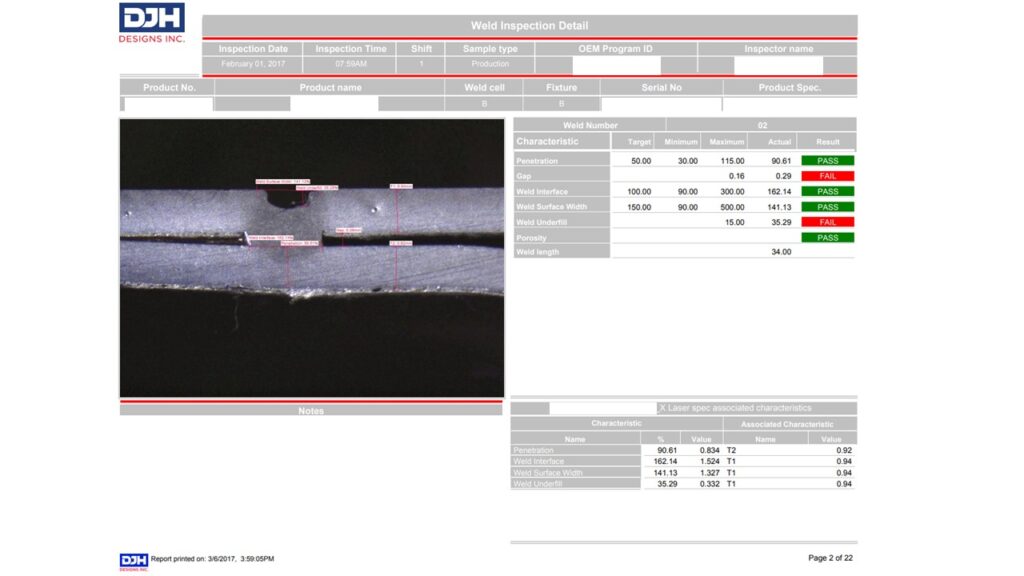

MEASUREMENT TOOLS AND REPORTS

Full collection of measurement tools, line segments, parallel line tools, radial tools, etc., as well as a full range of annotation tools to allow for unlimited markup of the images.

Data export utility. Any data can be sorted and exported to multiple formats for use in Excel, Minitab or number of other statistical analysis programs.

A standalone Report Manager Module can be licensed independently to the program. Supervisors, managers can license report manager to be installed on any PC (Desktop or Laptops) to be able generate reports from anywhere for all data in the system.

Corporate report Manager allows for generation of reports, or the export of any data from any plant anywhere in the world.

SOFTWARE DETAILS

SYSTEM SPECIFICATIONS

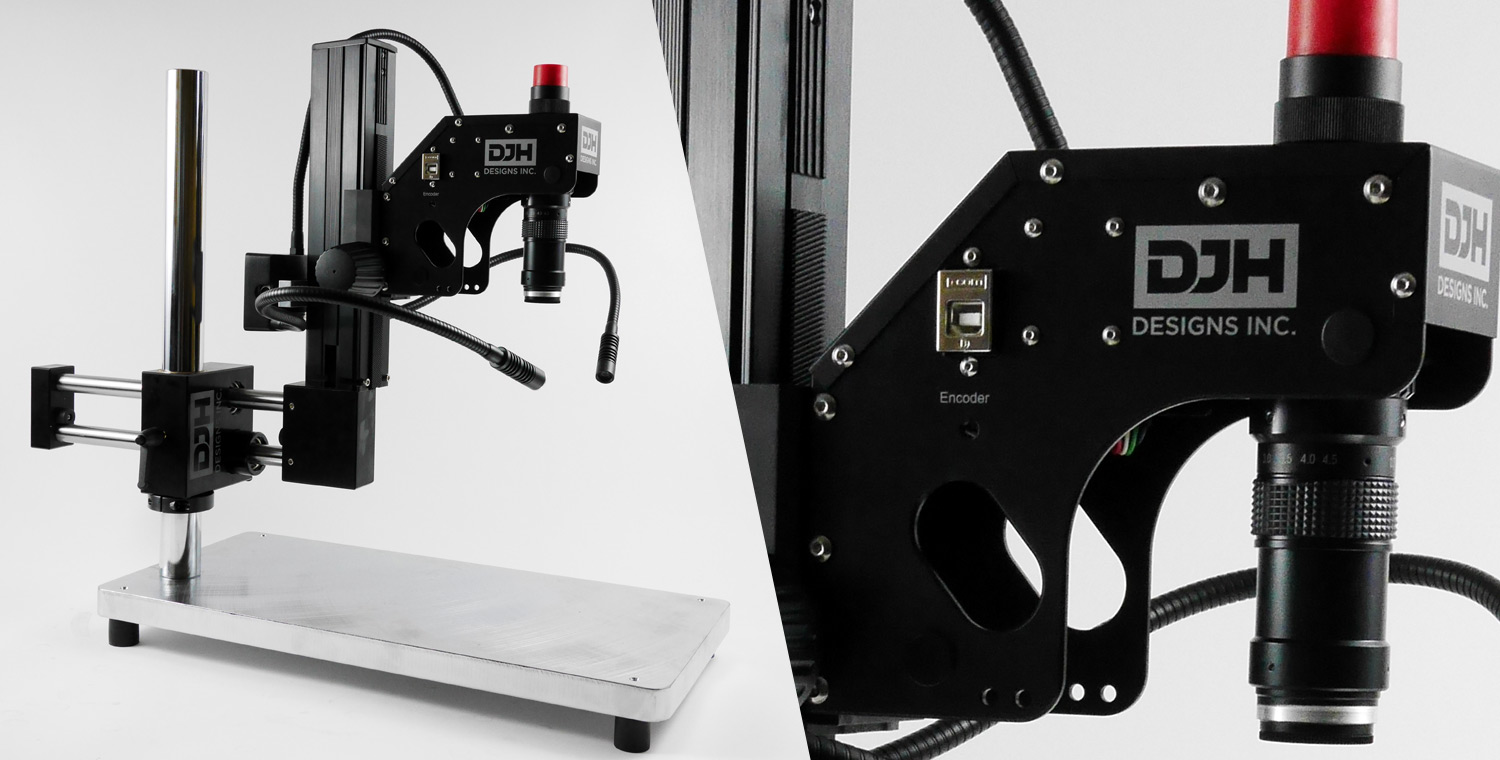

Flexible optical system options

Standard or inverted configurations: Standard zoom system with wide FOV means that the same optical system is capable of handling all welding types. Different configurations are available for a wide range of Weld types.

Recommended PC system specs for capture and workstations

Server Requirements