Roll Grinder

Features

- Wet Grinding keeps the surface of the roll cool, allowing for faster grinding rates than can be achieved by dry grinding

- By using coolant, the roll’s surface temperature is kept down, allowing for larger cuts and significantly faster grinding speeds

- Superior dust abatement and elimination of the hazardous fine dust associated with dry grinding

- Heavy-duty, high-speed grinder with variable speed control

- Heavy Duty High-Speed Precision Grinding Head

- Independent Roll Spin and Grinding Feed Rate controls

- Finish sanding attachment

- Filter bed

ADVANTAGES OF WET GRINDING VS DRY GRINDING

Superior Roll concentricity

DJH Designs Wet Grinding System utilizes our unique bearing cradle design to grind your rolls on their bearings. This process results in far superior roll concentricity than those systems that grind rolls on the shaft centers. Grinding with the bearings ensures the roll concentricity is true to the bearing journals, so your rolls run true when installed on the line.

Time Savings

Dry grinding can typically take up to 2 hours, depending on the roll type and finish required. It could take up to 4 hours to complete the grinding roll. The Typical wet grinding cycle can be done in as little as 15 minutes (excluding final sanding/polishing). It is common to completely grind and polish a roll in as little as 30 minutes.

Superior Roll finish with a single-pass grinding cycle

Dry grinding causes a significant heat buildup on the surface of the roll due to the friction of the grinding wheel in contact with the roll surface. This friction buildup causes surface distortions and can burn or damage the roll surface if too heavy a cut is attempted. Surface friction from dry grinding also exasperates a phenomenon called the bow wave effect. The bow wave effect is a pressure wave that builds up in the surface of the roll ahead of the leading edge of the grinding wheel, exactly the same way a boat creates a bow wave in the water ahead of its prow. As the cut’s depth increases, the friction also increases, and the coating becomes softer. This amplifies the bow wave effect. The grinding wheel also has a tendency to ride up on the wave, and as it rollercoasters over the pressure wave, if the feed rate is too high, you end up with micro ridges in the roll surface. Wet grinding significantly reduces the bow wave effect by keeping the surface of the roll well-cooled and lubricated so that you get a very clean cutting action on the face of the roll without the problem of ridges.

Low durometer rolls can be ground without any modification to the grinding process

Dry grinding of low-durometer rolls requires a significant change in the approach to grinding rolls. It requires lower feed rates and a greater reduction in the depth of each pass. This greatly increases the cycle time over wet grinding. With wet grinding, significantly altering the grinding process is unnecessary.

Dust abatement

Dry grinding requires the use of high-volume dust extractors to control the grinding dust coming off the roll. This dust is not only hazardous to the operator and the environment, but it is also a significant fire hazard. With the Wet Grinding System, there is no dust to contend with; the cutting fluid draws the grindings away as a slurry that is pumped into a filter bed and disposed of automatically into the hopper. Disposal is easy and can be included in your normal waste stream.

GRINDING HEAD

• Self-contained unit mounts to lathe cross slide

• Heavy-duty, special balanced spindle design and wheel hub

• Specially designed grinder chassis frame to absorb vibrations

• Heavy-duty wheel guard

• Long life smooth transmission belt drive

• Grinding wheel secured onto a 21⁄2” diameter hub, taper fit to 2” diameter shaft, fully balanced 10” diameter x 11⁄4” face x 21⁄2” bore grinding wheel.

• 7000 RPM wheel speed – Variable speed control

• Totally enclosed 10 HP 3ph, 440V motor special balance 3600 RPM

Standard Equipment:

• HD wheel guard

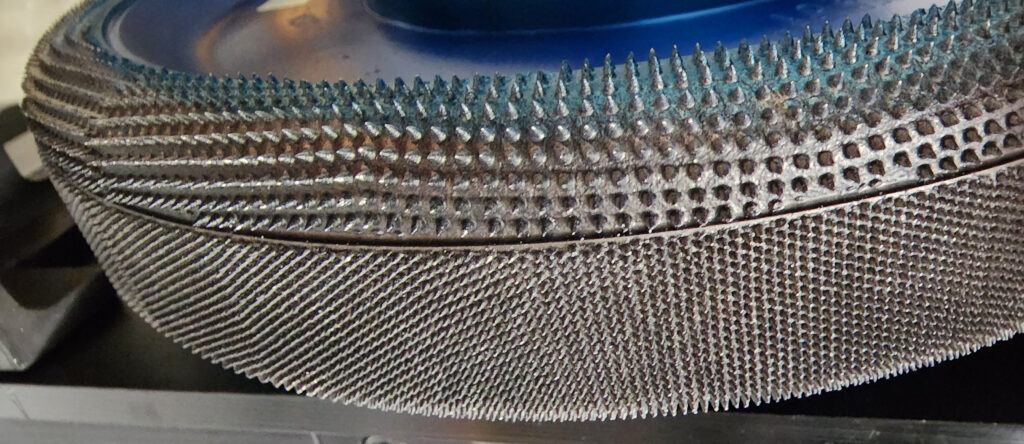

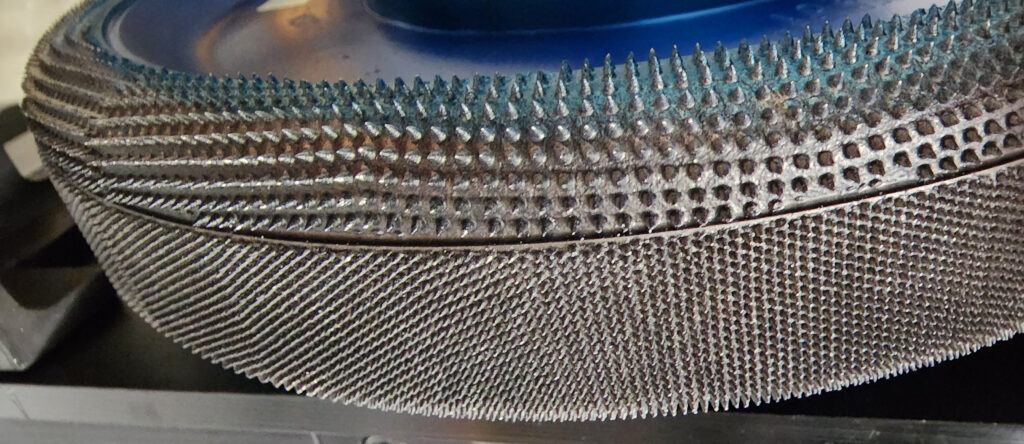

• 10” diameter x 11⁄4” face Rubberhog grinding wheel. One feature that makes the Rubberhog wheels your best choice for elastomer grinding is the wide selection of coating types and tooth sizes. This broad coating choice ensures we can offer a wide selection of grinding wheels to meet your requirements. The carbide teeth are positioned to provide fast penetration into the material, and unrestricted debris flow away from the wheel. This provides a free-cutting action, drastically reducing the time required for grinding. In conjunction, the finish sanding attachment provides the ability to finish rolls to a high degree of ultra-smooth roll finishes.

The combined selection of the grinding wheel tooth and finish pass paper grit ensures an ultra-smooth roll finish for the ultimate coating finish. Wheel type and finish paper selection can be tailored to meet the specific requirements of the customers’ application.

• Variable Speed Control

• Dynamic Brake

• Tool Kit

• Drive transmission guard

• Grinding wheel hub

LATHE

• Heavy-duty center lathe.

• Rapid traverse to cross and longitudinal slides by a separate motor.

• Automatic lubrication to carriage slides.

• Hardened and precision ground bedways.

• Roller bearing spindle.

• All geared totally enclosed headstock with hardened and ground gears and splines, forced and filtered oil supply to all parts.

• Roller Bearing Spindle with D1-11 camlock spindle nose.

• Multi-disk clutch for brake and drive both in forward and reverse mode.

• Totally enclosed quick change gearbox, positive oil feed.

Standard Equipment:

• Drive plate with coupling or, as shown, with optional 3-jaw self-centering 12” chuck.

• Chip tray

• Drive plate and coupling

• Steady rest

• Two dead centers and sleeve

• Set of change gears

• Work lamp

• DJH Designs Bearing Cradles with 1 set of bearing adapters to accommodate the different sizes in use with the plant.

Note: For rolls that utilize pillow block bearings, we typically recommend removing the pillow block bearing and installing a standard cartridge bearing to allow the roll to be ground on the bearing journals. Alternatively, as an option, the operator can install the centers and grind these specific rolls between centers with the same setup. When grinding on centers, you are relying on the condition of the shaft ends to control the concentricity of the roll.

• Special cradle to support the coater roll in its own bearings, guaranteeing concentricity between spindle bearings and coater surface. Squeegee roll can also be modified with bolt-on bearings to use the same features. Two sets of bearing adapters included (customer to provide bearing specifications).

• Sanding attachment for finishing roller surface.

• Tool kit

• Manuals

FILTER BED

The gravity bed filter is a continuous self-cleaning gravity filter. Solids are removed as liquid flows through the filter media and discharged relatively dry into an outside container.

An endless conveyor carries the blanket-type filter media. The conveyor’s sloping sides create a deep pool for the liquid, while an inclined discharge ramp provides carry-off for the waste.

As unfiltered liquid flows onto the filter media, it passes through the blanket and deposits solids on the media surface (thus forming an additional filtering stage). When the accumulation of waste appreciably slows the rate of liquid flow through the filter media, the level of standing liquid rises and actuates at the level of control. The motor-driven conveyor belt is advanced, dumping the waste off the end of the unit into your bin and bringing a section of fresh media into position under the liquid flow. The float control senses when the liquid flow has resumed its proper rate and controls media advance accordingly.

Standard Equipment:

• Filter paper

• Air-operated pumps

• Ratio motor

• Stand

• Tanks, pipe/ tube and fittings.

• One pail of coolant

• Coolant Spectrometer

TYPICAL GRINDING SYSTEM SPECIFICATIONS

Swing over cross slide 460mm

Distance between centers 4064mm

Spindle motor 15HP 3-phase

Spindle taper in nose/sleeve #8 MT

Spindle Nose D1-11 Camlock

Max. Weight of roll supported 900kg

Length of machine 5598mm

Width of machine 1280mm

Height of machine 2100mm**

Net Weight 3980kg**

Voltage 415 50/60Hz

3-phase

**Subject to change depending on options

FILTER BED

Length 2108mm

Width 940mm

Filter Media Width 762mm

Tank Capacity 386L

Dry Weight 262kg

Notes:

1) System is sized as per customer-supplied roll drawings and bearing specifications.

2) Customer to advise if sleeve assembly is used with the bearing or if the bearing fits directly in their bearing blocks (no sleeve adapter).

3) Rolls with cartridge-type bearings can only be ground on centers unless the cartridge bearing is removed and regular bearings are installed for the grinding process. Optional cradle adaptors are available for other bearing sizes if required.

To request a quote, please email sales@djh.com or fill our contact form.

ADVANTAGES OF WET GRINDING VS DRY GRINDING

Superior Roll concentricity

DJH Designs Wet Grinding System utilizes our unique bearing cradle design to grind your rolls on their bearings. This process results in far superior roll concentricity than those systems that grind rolls on the shaft centers. Grinding with the bearings ensures the roll concentricity is true to the bearing journals, so your rolls run true when installed on the line.

Time Savings

Dry grinding can typically take up to 2 hours, depending on the roll type and finish required. It could take up to 4 hours to complete the grinding roll. The Typical wet grinding cycle can be done in as little as 15 minutes (excluding final sanding/polishing). It is common to completely grind and polish a roll in as little as 30 minutes.

Superior Roll finish with a single-pass grinding cycle

Dry grinding causes a significant heat buildup on the surface of the roll due to the friction of the grinding wheel in contact with the roll surface. This friction buildup causes surface distortions and can burn or damage the roll surface if too heavy a cut is attempted. Surface friction from dry grinding also exasperates a phenomenon called the bow wave effect. The bow wave effect is a pressure wave that builds up in the surface of the roll ahead of the leading edge of the grinding wheel, exactly the same way a boat creates a bow wave in the water ahead of its prow. As the cut’s depth increases, the friction also increases, and the coating becomes softer. This amplifies the bow wave effect. The grinding wheel also has a tendency to ride up on the wave, and as it rollercoasters over the pressure wave, if the feed rate is too high, you end up with micro ridges in the roll surface. Wet grinding significantly reduces the bow wave effect by keeping the surface of the roll well-cooled and lubricated so that you get a very clean cutting action on the face of the roll without the problem of ridges.

Low durometer rolls can be ground without any modification to the grinding process

Dry grinding of low-durometer rolls requires a significant change in the approach to grinding rolls. It requires lower feed rates and a greater reduction in the depth of each pass. This greatly increases the cycle time over wet grinding. With wet grinding, significantly altering the grinding process is unnecessary.

Dust abatement

Dry grinding requires the use of high-volume dust extractors to control the grinding dust coming off the roll. This dust is not only hazardous to the operator and the environment, but it is also a significant fire hazard. With the Wet Grinding System, there is no dust to contend with; the cutting fluid draws the grindings away as a slurry that is pumped into a filter bed and disposed of automatically into the hopper. Disposal is easy and can be included in your normal waste stream.

GRINDING HEAD

• Self-contained unit mounts to lathe cross slide

• Heavy-duty, special balanced spindle design and wheel hub

• Specially designed grinder chassis frame to absorb vibrations

• Heavy-duty wheel guard

• Long life smooth transmission belt drive

• Grinding wheel secured onto a 21⁄2” diameter hub, taper fit to 2” diameter shaft, fully balanced 10” diameter x 11⁄4” face x 21⁄2” bore grinding wheel.

• 7000 RPM wheel speed – Variable speed control

• Totally enclosed 10 HP 3ph, 440V motor special balance 3600 RPM

Standard Equipment:

• HD wheel guard

• 10” diameter x 11⁄4” face Rubberhog grinding wheel. One feature that makes the Rubberhog wheels your best choice for elastomer grinding is the wide selection of coating types and tooth sizes. This broad coating choice ensures we can offer a wide selection of grinding wheels to meet your requirements. The carbide teeth are positioned to provide fast penetration into the material, and unrestricted debris flow away from the wheel. This provides a free-cutting action, drastically reducing the time required for grinding. In conjunction, the finish sanding attachment provides the ability to finish rolls to a high degree of ultra-smooth roll finishes.

The combined selection of the grinding wheel tooth and finish pass paper grit ensures an ultra-smooth roll finish for the ultimate coating finish. Wheel type and finish paper selection can be tailored to meet the specific requirements of the customers’ application.

• Variable Speed Control

• Dynamic Brake

• Tool Kit

• Drive transmission guard

• Grinding wheel hub

LATHE

• Heavy-duty center lathe.

• Rapid traverse to cross and longitudinal slides by a separate motor.

• Automatic lubrication to carriage slides.

• Hardened and precision ground bedways.

• Roller bearing spindle.

• All geared totally enclosed headstock with hardened and ground gears and splines, forced and filtered oil supply to all parts.

• Roller Bearing Spindle with D1-11 camlock spindle nose.

• Multi-disk clutch for brake and drive both in forward and reverse mode.

• Totally enclosed quick change gearbox, positive oil feed.

Standard Equipment:

• Drive plate with coupling or, as shown, with optional 3-jaw self-centering 12” chuck.

• Chip tray

• Drive plate and coupling

• Steady rest

• Two dead centers and sleeve

• Set of change gears

• Work lamp

• DJH Designs Bearing Cradles with 1 set of bearing adapters to accommodate the different sizes in use with the plant.

Note: For rolls that utilize pillow block bearings, we typically recommend removing the pillow block bearing and installing a standard cartridge bearing to allow the roll to be ground on the bearing journals. Alternatively, as an option, the operator can install the centers and grind these specific rolls between centers with the same setup. When grinding on centers, you are relying on the condition of the shaft ends to control the concentricity of the roll.

• Special cradle to support the coater roll in its own bearings, guaranteeing concentricity between spindle bearings and coater surface. Squeegee roll can also be modified with bolt-on bearings to use the same features. Two sets of bearing adapters included (customer to provide bearing specifications).

• Sanding attachment for finishing roller surface.

• Tool kit

• Manuals

FILTER BED

The gravity bed filter is a continuous self-cleaning gravity filter. Solids are removed as liquid flows through the filter media and discharged relatively dry into an outside container.

An endless conveyor carries the blanket-type filter media. The conveyor’s sloping sides create a deep pool for the liquid, while an inclined discharge ramp provides carry-off for the waste.

As unfiltered liquid flows onto the filter media, it passes through the blanket and deposits solids on the media surface (thus forming an additional filtering stage). When the accumulation of waste appreciably slows the rate of liquid flow through the filter media, the level of standing liquid rises and actuates at the level of control. The motor-driven conveyor belt is advanced, dumping the waste off the end of the unit into your bin and bringing a section of fresh media into position under the liquid flow. The float control senses when the liquid flow has resumed its proper rate and controls media advance accordingly.

Standard Equipment:

• Filter paper

• Air-operated pumps

• Ratio motor

• Stand

• Tanks, pipe/ tube and fittings.

• One pail of coolant

• Coolant Spectrometer

TYPICAL GRINDING SYSTEM SPECIFICATIONS

Swing over cross slide 460mm

Distance between centers 4064mm

Spindle motor 15HP 3-phase

Spindle taper in nose/sleeve #8 MT

Spindle Nose D1-11 Camlock

Max. Weight of roll supported 900kg

Length of machine 5598mm

Width of machine 1280mm

Height of machine 2100mm**

Net Weight 3980kg**

Voltage 415 50/60Hz

3-phase

**Subject to change depending on options

FILTER BED

Length 2108mm

Width 940mm

Filter Media Width 762mm

Tank Capacity 386L

Dry Weight 262kg

Notes:

1) System is sized as per customer-supplied roll drawings and bearing specifications.

2) Customer to advise if sleeve assembly is used with the bearing or if the bearing fits directly in their bearing blocks (no sleeve adapter).

3) Rolls with cartridge-type bearings can only be ground on centers unless the cartridge bearing is removed and regular bearings are installed for the grinding process. Optional cradle adaptors are available for other bearing sizes if required.

Roll Grinder

Features

- Wet Grinding keeps the surface of the roll cool, allowing for faster grinding rates than can be achieved by dry grinding

- By using coolant, the roll’s surface temperature is kept down, allowing for larger cuts and significantly faster grinding speeds

- Superior dust abatement and elimination of the hazardous fine dust associated with dry grinding

- Heavy-duty, high-speed grinder with variable speed control

- Heavy Duty High-Speed Precision Grinding Head

- Independent Roll Spin and Grinding Feed Rate controls

- Finish sanding attachment

- Filter bed